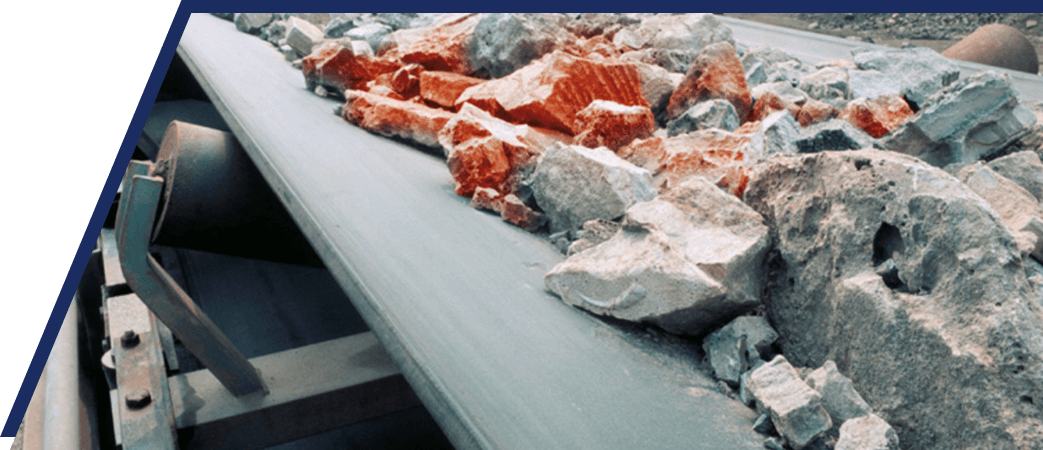

Covers

Developed to withstand the most adverse conditions and offer the lowest cost per ton transported, the High Performance HDS-EXTREME®, HDS-IMPACT®, HDS-MINA®, HDS-MINERAÇÃO® AND HDS-W® Covers are the result of a professional work of our Research and Development Department, which is constantly dedicated to formulating high quality compounds with a focus on safety, durability and, above all, resistance in extreme use applications.

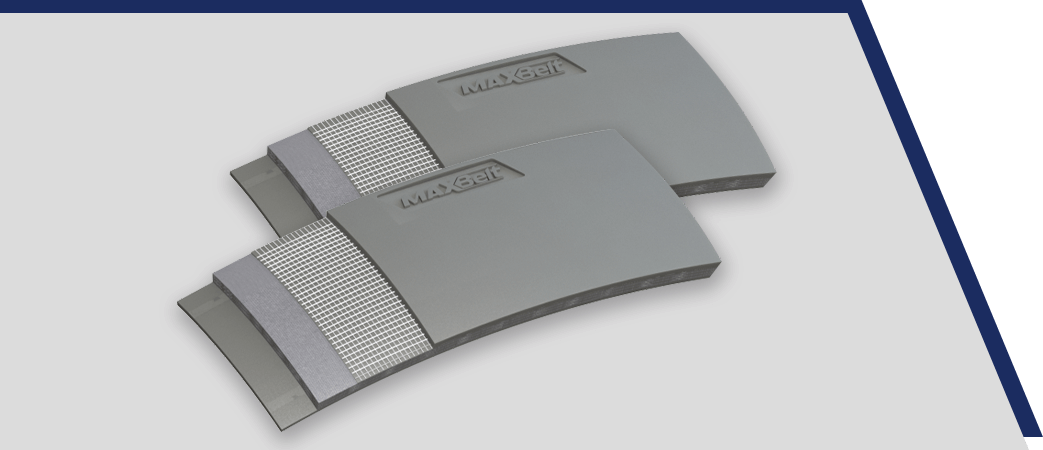

Rip Stop Steel Max®

Special cover composed of high-resistance steel mesh, indicated for application in the upper or lower layer of the belt, providing greater protection to the carcass against cuts and tears, being recommended for applications in equipment without the presence of metal detectors and that require maximum belt durability.

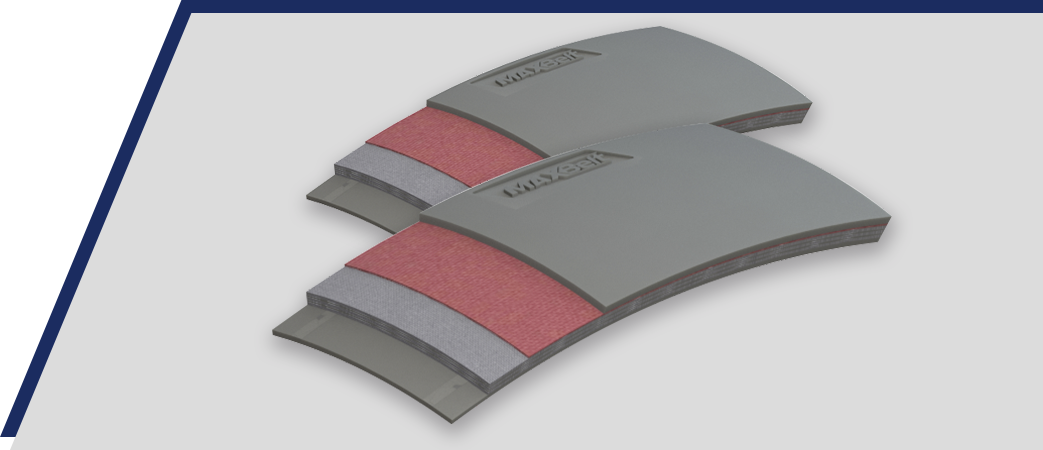

Rip Stop Aramida Max®

Applied on the upper or lower cover of the belts, the presence of the Aramid textile layer provides high resistance to perforation and cuts, without restrictions of use in the midst of equipment with metal detectors. With Rip Stop Aramid Max®, operational safety brings with it more durability and profitability in the final cost per ton transported.

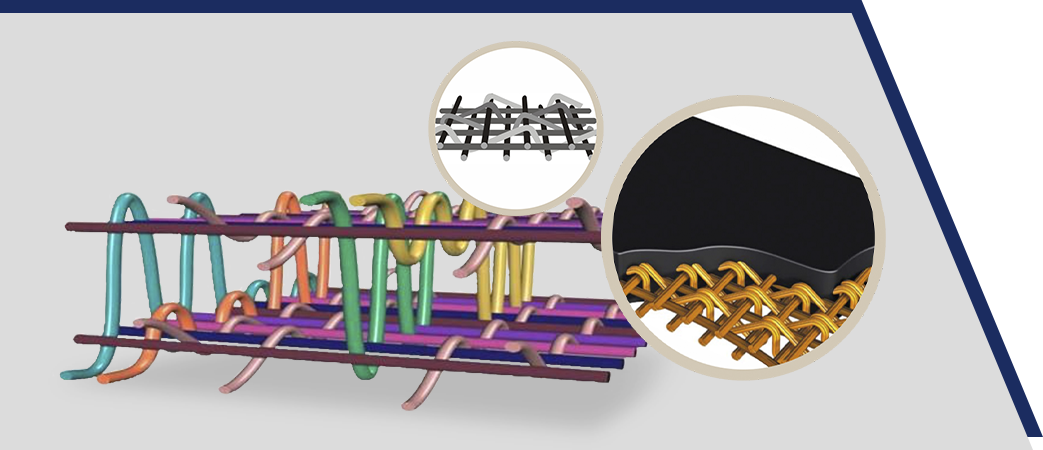

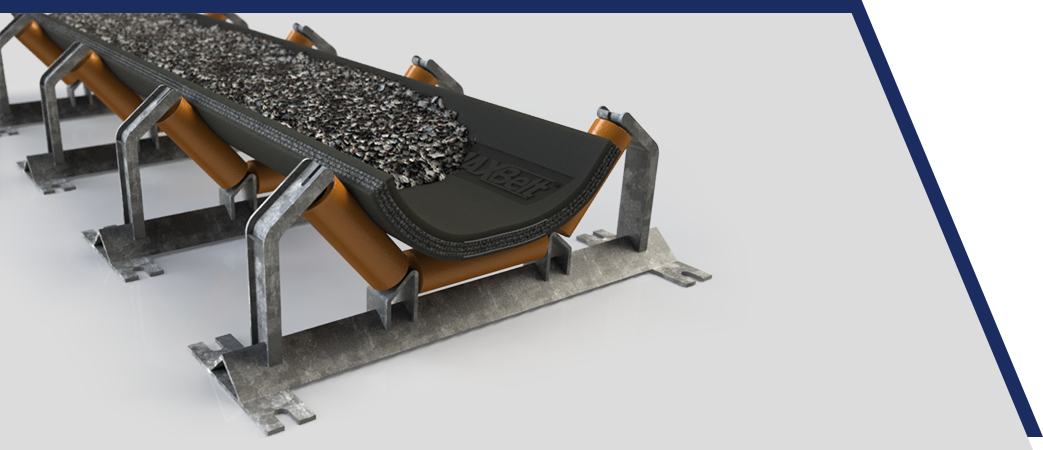

Straight Warp®Belts

Constructed based on the intelligent combination of components with the presence of straight warp yarn wrapped in weft and high strength nylon knotting yarn, Straight Warp Belts (SW) have advanced structural quality in relation to traditional belts, offering more durability combined with low elongation factor, as well as high impact resistance, drastically reducing carcass damage.

Wear Indicator®

Developed and patented by MAXBELT, this product was designed to facilitate and improve the logistics of purchasing belts and their scheduled replacement, that is, a product made to enable professional management of conveyors, including the customer’s autonomy to choose the point security that best suits your activity.

MAXBELT Self-Centering®Belts

A solution that provides accurate and automatic alignment in the midst of transport lines, having technical qualities that overcome the routine challenges of reversible conveyors that are difficult to align (or with structural problems) and mobile feeds that present complexities in the centralization of loads.